Abstract

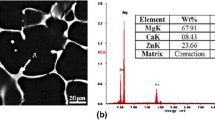

An approach of achieving high ductility as well as respectable high strength for low-Zn-containing wrought Mg alloy is presented in this paper. A low-cost and industry-compatible Mg–2Zn–0.3Mn–0.2La–0.1Ce alloy with highest yield strength (YS) of 289 MPa, ultimate tensile strength (UTS) of 300 MPa and excellent elongation (EL) of 32.7% is developed by traditional indirect extrusion. The microstructure and macro-textures of this alloy under various extrusion temperatures are characterized by OM, EBSD and XRD analysis. High quantity of dispersed elongated un-DRXed grains with various orientations form at relatively low extrusion temperatures, and many of them possess high basal Schmidt Factors (SFs) toward transverse directions. TEM analysis reveals a large number of networked dislocations passing through the deformation bands along transverse directions within the un-DRXed grains, which suggests the integral deformation (bending) is achievable by dislocation motion. It is believed that the high ductility along extrusion direction is induced by the bendable elongated un-DRXed grains during tensile deformation by embodying the easy-to-failure regions, preventing the subsequent generation of micro-cracks and accommodating the stress concentration.

Similar content being viewed by others

References

Sabat RK, Mishra RK, Sachdev AK, Suwas S (2015) The deciding role of texture on ductility in a Ce containing Mg alloy. Mater Lett 153:158–161

Liu P, Jiang H, Cai Z, Kang Q, Zhang Y (2016) The effect of Y, Ce and Gd on texture, recrystallization and mechanical property of Mg–Zn alloys. J Magn Alloy 4(3):188–196

Du YZ, Qiao XG, Zheng MY, Wu K, Xu SW (2015) Development of high-strength, low-cost wrought Mg–2.5mass% Zn alloy through micro-alloying with Ca and La. Mater Des 85:549–557

Langelier B, Nasiri AM, Lee SY, Gharghouri MA, Esmaeili S (2015) Improving microstructure and ductility in the Mg–Zn alloy system by combinational Ce–Ca microalloying. Mater Sci Eng A 620:76–84

Tong LB, Zhang QX, Jiang ZH, Zhang JB, Meng J, Cheng LR, Zhang HJ (2016) Microstructures, mechanical properties and corrosion resistances of extruded Mg–Zn–Ca–xCe/La alloys. J Mech Behav Biomed 62:57–70

Park SH, You BS, Mishra RK, Sachdev AK (2014) Effects of extrusion parameters on the microstructure and mechanical properties of Mg–Zn–(Mn)–Ce/Gd alloys. Mater Sci Eng A 598:396–406

Zhang BP, Geng L, Huang LJ, Zhang XX, Dong CC (2010) Enhanced mechanical properties in fine-grained Mg–1.0Zn–0.5Ca alloys prepared by extrusion at different temperatures. Scr Mater 63(10):1024–1027

Gupta M, Sharon NML (2011) Magnesium, magnesium alloys, and magnesium composites. John Wiley & Sons, Inc., Hoboken, New Jersey

She Q, Yan H, Chen J, Su B, Yu Z, Chen C, Xia W (2017) Microstructure characteristics and liquation behavior of fiber laser welded joints of Mg-5Zn-1Mn-0.6Sn alloy sheets. Trans Nonferr Metal Soc 27(4):812–819

Bohlen J, Nürnberg MR, Senn JW, Letzig D, Agnew SR (2007) The texture and anisotropy of magnesium–zinc–rare earth alloy sheets. Acta Mater 55(6):2101–2112

Somekawa H, Mukai T (2007) High strength and fracture toughness balance on the extruded Mg–Ca–Zn alloy. Mater Sci Eng A 459(1):366–370

Bu F, Yang Q, Guan K, Qiu X, Zhang D, Sun W, Zheng T, Cui X, Sun S, Tang Z, Liu X, Meng J (2016) Study on the mutual effect of La and Gd on microstructure and mechanical properties of Mg-Al-Zn extruded alloy. J Alloy Compd 688:1241–1250

Jeong HY, Kim B, Kim SG, Kim HJ, Park SS (2014) Effect of Ce addition on the microstructure and tensile properties of extruded Mg–Zn–Zr alloys. Mater Sci Eng A 612:217–222

Tong LB, Zhang JB, Zhang QX, Jiang ZH, Xu C, Kamado S, Zhang DP, Meng J, Cheng LR, Zhang HJ (2016) Effect of warm rolling on the microstructure, texture and mechanical properties of extruded Mg–Zn–Ca–Ce/La alloy. Mater Charact 115:1–7

Yu H, Kim YM, You BS, Yu HS, Park SH (2013) Effects of cerium addition on the microstructure, mechanical properties and hot workability of ZK60 alloy. Mater Sci Eng A 559:798–807

Medina J, Pérez P, Garcés G, Adeva P (2017) Effects of calcium, manganese and cerium-rich mischmetal additions on the mechanical properties of extruded Mg-Zn-Y alloy reinforced by quasicrystalline I-phase. Mater Charact 129:195–206

Zengin H, Turen Y (2018) Effect of La content and extrusion temperature on microstructure, texture and mechanical properties of Mg-Zn-Zr magnesium alloy. Mater Chem Phys 214:421–430

Ke H, Chunyu L, Guojun X, Ruizhen G, Qichi L, Qiyu L (2019) Effect of extrusion temperature on the microstructure and mechanical properties of low Zn containing wrought Mg alloy micro-alloying with Mn and La-rich misch metal. Mater Sci Eng A. 742:692–703

Koike J (2005) Enhanced deformation mechanisms by anisotropic plasticity in polycrystalline Mg alloys at room temperature. Metall Mater Trans A 36(7):1689–1696

Rong W, Zhang Y, Wu Y, Chen Y, Sun M, Chen J, Peng L (2019) The role of bimodal-grained structure in strengthening tensile strength and decreasing yield asymmetry of Mg-Gd-Zn-Zr alloys. Mater Sci Eng A 740–741:262–273

Homma T, Hinata J, Kamado S (2012) Development of an extruded Mg–Zn–Ca-based alloy: new insight on the role of Mn addition in precipitation. Philos Mag 92(12):1569–1582

Wang J-Y, Saufan A, Lin PH, Bor HY, Lee S, Kawamura Y (2014) Mechanical properties and strengthening behavior of Mg–Zn–MM alloy. Mater Chem Phys 148(1):28–31

Huang ML, Li HX, Ding H, Ren YP, Hao SM (2008) Isothermal section of Mg-Zn-La system in Mg rich corner at 350°C. Acta Metall Sin-Engl 21(5):329–335

Basu I, Al-Samman T (2015) Twin recrystallization mechanisms in magnesium-rare earth alloys. Acta Mater 96:111–132

Pan H, Yang C, Yang Y, Dai Y, Zhou D, Chai L, Huang Q, Yang Q, Liu S, Ren Y, Qin G (2019) Ultra-fine grain size and exceptionally high strength in dilute Mg–Ca alloys achieved by conventional one-step extrusion. Mater Lett 237:65–68

Chino Y, Kado M, Mabuchi M (2008) Compressive deformation behavior at room temperature – 773K in Mg–0.2mass% (0.035at.%)Ce alloy. Acta Mater 56(3):387–394

Jiang MG, Xu C, Nakata T, Yan H, Chen RS, Kamado S (2017) Enhancing strength and ductility of Mg-Zn-Gd alloy via slow-speed extrusion combined with pre-forging. J Alloy Compd 694:1214–1223

Kim S-H, Bae SW, Lee SW, Moon BG, Kim HS, Kim YM, Yoon J, Park SH (2018) Microstructural evolution and improvement in mechanical properties of extruded AZ31 alloy by combined addition of Ca and Y. Mater Sci Eng A 725:309–318

Jiang MG, Xu C, Nakata T, Yan H, Chen RS, Kamado S (2016) Rare earth texture and improved ductility in a Mg-Zn-Gd alloy after high-speed extrusion. Mater Sci Eng A 667:233–239

Bohlen J, Yi S, Letzig D, Kainer KU (2010) Effect of rare earth elements on the microstructure and texture development in magnesium–manganese alloys during extrusion. Mater Sci Eng A 527(26):7092–7098

Brömmelhoff K, Huppmann M, Reimers W (2011) The effect of heat treatments on the microstructure, texture and mechanical properties of the extruded magnesium alloy ME21. Int J Mater Res 102(9):1133–1141

Luo AA, Mishra RK, Sachdev AK (2011) High-ductility magnesium–zinc–cerium extrusion alloys. Scr Mater 64(5):410–413

Gao L, Yan H, Luo J, Luo AA, Chen R (2013) Microstructure and mechanical properties of a high ductility Mg–Zn–Mn–Ce magnesium alloy. J Magn Alloy 1(4):283–291

Kim D-W, Suh B-C, Shim M-S, Bae JH, Kim DH, Kim NJ (2013) Texture evolution in Mg-Zn-Ca alloy sheets. Metall Mater Trans A 44(7):2950–2961

Liu L, Chen X, Pan F, Gao S, Zhao C (2016) A new high-strength Mg-Zn-Ce-Y-Zr magnesium alloy. J Alloy Compd 688:537–541

Jäger A, Gärtnerová V, Mukai T (2014) Micromechanisms of grain refinement during extrusion of Mg–0.3at.% Al at low homologous temperature. Mater Charact 93:102–109

Pan F, Mao J, Zhang G, Tang A, She J (2016) Development of high-strength, low-cost wrought Mg–2.0mass% Zn alloy with high Mn content. Prog Nat Sci: Mater Int 26(6):630–635

Pantleon W (2008) Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction. Scr Mater 58(11):994–997

Griffiths D (2015) in Robson J (ed) The School of Materials. PhD Thesis, The University of Manchester, Manchester, UK

Wang Q, Shen Y, Jiang B, Tang A, Song J, Jiang Z, Yang T, Huang G, Pan F (2018) A micro-alloyed Mg-Sn-Y alloy with high ductility at room temperature. Mater Sci Eng A 735:131–144

Bohlen J, Yi SB, Swiostek J, Letzig D, Brokmeier HG, Kainer KU (2005) Microstructure and texture development during hydrostatic extrusion of magnesium alloy AZ31. Scr Mater 53(2):259–264

Alaneme KK, Okotete EA (2017) Enhancing plastic deformability of Mg and its alloys—a review of traditional and nascent developments. J Magn Alloy 5(4):460–475

Kim S-H, Jo W-K, Hong W-H, Kim W, Yoon J, Park SH (2017) Microstructural evolution of extruded AZ31 alloy with bimodal structure during compression. Mater Sci Eng A 702:1–9

Acknowledgements

The authors are also grateful for the co-support by HENAN JIEMEITE MAGNESIUM TECHNOLOGY CO., LTD. This research was financially supported by the National Key Research and Development Program of China [2016YFB0301104] and National Natural Science Foundation of China [51771043].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, K., Liao, Q., Li, C. et al. High ductility induced by un-DRXed grains in a Mg–Zn–Mn–La–Ce alloy. J Mater Sci 54, 10902–10917 (2019). https://doi.org/10.1007/s10853-019-03624-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03624-3