Abstract

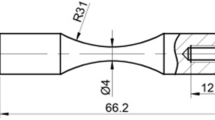

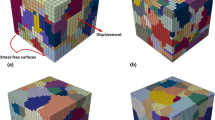

Fatigue crack initiation (FCI) in the very high cycle fatigue (VHCF) regime for an AA7075-T6 alloy has been estimated by introducing fatigue indicator parameters (FIPs) serving as the driving force for FCI via crystal plasticity finite element model (CPFEM). Extreme value distribution (EVD) of FIPs is computed based on the statistical volume elements extracted in the material microstructure by DREAM.3D software. The EVD is fitted to the Gumbel extreme distribution and the characteristic parameters are analyzed to evaluate the FCI driving force and the “hot-spot” of crack initiation for the AA 7075-T6 under cyclic straining in the VHCF regime. Moreover, the apparent Schmid factor (SF) of the slip system with the highest FIPs and equivalent grain size of the grains with the highest FIPs are calculated to estimate the possibility of crack initiation, and the effects of grain size on the FCI are discussed. Representative ultrasonic fatigue experiments for three stress levels corresponding to the cyclic strain magnitude of 0.254%, 0.289%, and 0.312% are conducted to verify the estimation of fatigue crack formation via CPFEM simulation. The accumulated plastic slip was found to be a necessary condition for forming fatigue cracks, in addition, the fatigue cracks with higher SF and in the larger grain size were more likely to originate. FIPs extreme distributions parameters were also assessed to agree well with the experimental results.

Similar content being viewed by others

Abbreviations

- FCI:

-

Fatigue crack initiation

- VHCF:

-

Very high cycle fatigue

- CPFEM:

-

Crystal plasticity finite element model

- EVD:

-

Extreme value distribution

- SVEs:

-

Statistical volume elements

- SF:

-

Schmid factor

- HCF:

-

High cycle fatigue

- FIPFS :

-

Fatemi–Socie FIPs

- RVE:

-

Representative volume element

- LCF:

-

Low cycle fatigue

- IHG:

-

Microstructurally small crack

- CRSS:

-

Critical resolved shear stress

- UMAT:

-

User-defined material subroutine

- F e :

-

Elastic deformation gradients

- F p :

-

Plastic deformation gradients

- L p :

-

Plastic velocity gradient

- \(\dot{\gamma }^{(\infty )}\) :

-

Dislocation slip rate on the αth slip system

- s (α) :

-

Slip direction on the αth active slip system

- m (α) :

-

The normal direction of slip plane on the αth active slip system

- \(\dot{F}^{p}\) :

-

The evolution rate of deformation gradient Fp

- \(\mathrm{\dot{\gamma }}_{0}\) :

-

Reference shear strain rate

- g α :

-

Drag stress of the slip system α

- τ α :

-

Resolved shear stress of slip system α

- χ α :

-

Cyclic kinematic hardening parameter

- h i :

-

Material constants (i = 1,2)

- r i :

-

Material constants (i = 1,2)

- σ :

-

Second-order Cauchy stress tensor

- C :

-

The 4th elasticity tensor

- E e :

-

The elastic Green strain tensor

- I :

-

Identity tensor

- h α β :

-

Latent hardening parameter

- R:

-

Stress ratio

- C 11 :

-

Elastic constant of AA7075-T6

- C 12 :

-

Elastic constant of AA7075-T6

- C 44 :

-

Elastic constant of AA7075-T6

- σ a :

-

Stress amplitude

- ε a :

-

Strain amplitude

- N f :

-

Fatigue fracture life

- \(\Delta \gamma_{p}^{\max }\) :

-

Maximum cyclic plastic shear strain range

- σ max :

-

Peak normal stress

- σ y :

-

Macroscopic yield strength of the material

- k :

-

Material constant

- α n :

-

The inverse measure of the dispersion

- n :

-

Sample size

- u n :

-

The largest characteristic value of the sampled population

- j :

-

The rank order of the FIPs

- R 2 :

-

Regression coefficient

References

Przybyla CP, McDowell DL (2012) Microstructure-sensitive extreme-value probabilities of high-cycle fatigue for surface vs subsurface crack formation in duplex Ti–6Al–4V. Acta Mater 60(1):293–305

Fatemi A, Socie DF (1988) A critical plane approach to multiaxial fatigue damage including out-of-phase loading. Fatigue Fract Eng M 11(3):149–165

Stopka KS, McDowell DL (2020) Microstructure-sensitive computational estimates of driving forces for surface versus subsurface fatigue crack formation in duplex Ti-6Al-4V and Al 7075–T6. JOM-US 72(1):28–38

Karr U, Schönbauer B, Fitzka M, Tamura E, Sandaiji Y, Murakami S, Mayer H (2019) Inclusion initiated fracture under cyclic torsion very high cycle fatigue at different load ratios. Int J Fatigue 122:199–207

Tanaka K, Akiniwa Y (2010) Fatigue crack propagation behaviour derived from S-N data in very high cycle regime. Fatigue Fract Eng M 25(8–9):775–784

Marines I, Bin X, Bathias C (2003) An understanding of very high cycle fatigue of metals. Int J Fatigue 25(9–11):1101–1107

Shiozawa K, Morii Y, Nishino S, Lu L (2006) Subsurface crack initiation and propagation mechanism in high-strength steel in a very high cycle fatigue regime. Int J Fatigue 28(11):1521–1532

Günther J, Krewerth D, Lippmann T, Leuders S, Tröster T, Weidner A, Biermann H, Niendorf T (2017) Fatigue life of additively manufactured Ti–6Al–4V in the very high cycle fatigue regime. Int J Fatigue 94:236–245

Zuo JH, Wang ZG, Han EH (2008) Effect of microstructure on ultra-high cycle fatigue behavior of Ti–6Al–4V. Mater Sci Eng A 473(1):147–152

Szczepanski CJ, Jha SK, Larsen JM, Jones JW (2008) Microstructural influences on very-high-cycle fatigue-crack initiation in Ti-6246. Metall Mater Trans A 39(12):2841–2851

Marines I, Bin X, Bathias C (2003) An understanding of very high cycle fatigue of metals. Int J Fatigue 25(9):1101–1107

Xue HQ, Bayraktar E, Bathias C (2011) Fatigue behavior and damage mechanism of a cast aluminum alloy in very high cycle regime. Adv Mater Res 264–265:706–711

Weiland H, Nardiello J, Zaefferer S, Cheong S, Papazian J, Raabe D (2009) Microstructural aspects of crack nucleation during cyclic loading of AA7075-T651. ENG FRACT MECH 76(5):709–714

Gao T, Sun Z, Xue H, Retraint D (2020) Effect of surface mechanical attrition treatment on high cycle and very high cycle fatigue of a 7075–T6 aluminium alloy. Int J Fatigue 139:105798

McDowell DL, Dunne F (2010) Microstructure-sensitive computational modeling of fatigue crack formation. Int J Fatigue 32(9):1521–1542

Cai G, Li C, Wang D, Zhou Y (2018) Investigation of annealing temperature on microstructure and texture of Fe-19Cr-2Mo-Nb-Ti ferritic stainless steel. Mater Charact 141:169–176

Cailletaud G, Forest S, Jeulin D, Feyel F, Galliet I, Mounoury V, Quilici S (2003) Some elements of microstructural mechanics. Comp Mater Sci 27(3):351–374

Stopka KS, Gu T, McDowell DL (2020) Effects of algorithmic simulation parameters on the prediction of extreme value fatigue indicator parameters in duplex Ti-6Al-4V. INT J FATIGUE 141:105865

Kanit T, Forest S, Galliet I, Mounoury V, Jeulin D (2003) Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int J Solids Struct 40(13–14):3647–3679

Gu T, Medy J, Klosek V, Castelnau O, Forest S, Herve-Luanco E, Lecouturier Dupouy F, Proudhon H, Renault P, Thilly L (2019) Multiscale modeling of the elasto-plastic behavior of architectured and nanostructured Cu-Nb composite wires and comparison with neutron diffraction experiments. Int J Plasticity 122:1–30

Murakami Y, Kodama S, Konuma S (1989) Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. I: Basic fatigue mechanism and evaluation of correlation between the fatigue fracture stress and the size and location of non-metallic inclusions. Int J Fatigue 11(5):291–298

Przybyla CP. Microstructure-sensitive extreme value probabilities of fatigue in advanced engineering alloys.: Georgia Institute of Technology (2010).

Przybyla CP, McDowell DL (2011) Simulated microstructure-sensitive extreme value probabilities for high cycle fatigue of duplex Ti–6Al–4V. Int J Plasticity 27(12):1871–1895

Przybyla CP, McDowell DL (2010) Microstructure-sensitive extreme value probabilities for high cycle fatigue of Ni-base superalloy IN100. Int J Plasticity 26(3):372–394

Prasannavenkatesan R, Zhang J, McDowell DL, Olson GB, Jou H (2009) 3D modeling of subsurface fatigue crack nucleation potency of primary inclusions in heat treated and shot peened martensitic gear steels. Int J Fatigue 31(7):1176–1189

Findley KO, Saxena A (2006) Low cycle fatigue in Rene 88DT at 650 C: crack nucleation mechanisms and modeling. Metall Mater Trans A 37(5):1469–1475

Shenoy M, Zhang J, McDowell DL (2007) Estimating fatigue sensitivity to polycrystalline Ni-base superalloy microstructures using a computational approach. Fatigue Fract Eng M 30(10):889–904

Socie D. Critical plane approaches for multiaxial fatigue damage assessment. Advances in multiaxial fatigue (1993).

Gu T, Stopka KS, Xu C, McDowell DL (2020) Prediction of maximum fatigue indicator parameters for duplex Ti–6Al–4V using extreme value theory. Acta Mater 188:504–516

Lucarini S, Segurado J. An upscaling approach for micromechanics based fatigue: from RVEs to specimens and component life prediction. Int J Fracture. 2019:1–16.

Przybyla C, Prasannavenkatesan R, Salajegheh N, McDowell DL (2010) Microstructure-sensitive modeling of high cycle fatigue. Int J Fatigue 32(3):512–525

Stopka KS, McDowell DL (2020) Microstructure-sensitive computational multiaxial fatigue of Al 7075–T6 and duplex Ti-6Al-4V. Int J Fatigue 133:105460

Stopka KS, Yaghoobi M, Allison JE, McDowell DL (2021) Effects of boundary conditions on microstructure-sensitive fatigue crystal plasticity analysis. Integr Mater Manuf Innov 10(3):393–412

Yaghoobi M, Stopka KS, Lakshmanan A, Sundararaghavan V, Allison JE, McDowell DL (2021) PRISMS-Fatigue computational framework for fatigue analysis in polycrystalline metals and alloys. NPJ Comput Mater 7(1):38

Groeber MA, Jackson MA (2014) DREAM. 3D: a digital representation environment for the analysis of microstructure in 3D. Integr Materi Manuf Innov. 3(1):56–72

Yaghoobi M, Stopka KS, Lakshmanan A, Sundararaghavan V, Allison JE, McDowell DL (2021) PRISMS-Fatigue computational framework for fatigue analysis in polycrystalline metals and alloys. NPJ Comput Mater 7(1):1–12

Hennessey C, Castelluccio GM, McDowell DL (2017) Sensitivity of polycrystal plasticity to slip system kinematic hardening laws for Al 7075–T6. Mater Sci Eng A 687:241–248

McDowell DL (1995) Stress state dependence of cyclic ratchetting behavior of two rail steels. Int J Plasticity 11(4):397–421

Zhao T, Jiang Y (2008) Fatigue of 7075–T651 aluminum alloy. Int J Fatigue 30(5):834–849

Sauzay M, Jourdan T (2006) Polycrystalline microstructure, cubic elasticity, and nucleation of high-cycle fatigue cracks. Int J Fracture 141(3–4):431–446

Musinski WD, McDowell DL (2012) Microstructure-sensitive probabilistic modeling of HCF crack initiation and early crack growth in Ni-base superalloy IN100 notched components. Int J Fatigue 37:41–53

Castelluccio GM, McDowell DL (2015) Microstructure and mesh sensitivities of mesoscale surrogate driving force measures for transgranular fatigue cracks in polycrystals. Mater Sci Eng A 639:626–639

Castelluccio GM, McDowell DL (2014) Mesoscale modeling of microstructurally small fatigue cracks in metallic polycrystals. Mater Sci Eng A 598:34–55

Tallman AE, Swiler LP, Wang Y, McDowell DL. Reconciled top-down and bottom-up hierarchical multiscale calibration of bcc Fe crystal plasticity. Int J Multiscale Com. 2017;15(6).

Li J, Proudhon H, Roos A, Chiaruttini V, Forest S (2014) Crystal plasticity finite element simulation of crack growth in single crystals. Comp Mater Sci 94:191–197

Bridier F, McDowell DL, Villechaise P, Mendez J (2009) Crystal plasticity modeling of slip activity in Ti–6Al–4V under high cycle fatigue loading. Int J Plasticity 25(6):1066–1082

Stopka KS. Integrated computational materials engineering workflows for microstructure-sensitive fatigue of advanced alloys. Georgia Institute of Technology; 2021.

Acknowledgements

The authors are grateful for the supports provided by the National Natural Science Foundation of China (91860206), Shaanxi Province Key Research and Development Program (2019KW-063), and thank you for the contribution of Zhi Qin from Northwestern Polytechnical University.

Author information

Authors and Affiliations

Contributions

BL Methodology, Writing, original draft, review and editing. ZS Editing and review; HX Resources, Funding acquisition; TG Data curation, experiments.

Corresponding authors

Additional information

Handling Editor: M. Grant Norton .

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, B., Gao, T., Xue, H. et al. Estimation of fatigue crack initiation in the very high cycle fatigue regime for AA7075-T6 alloy using crystal plasticity finite element method. J Mater Sci 57, 10649–10663 (2022). https://doi.org/10.1007/s10853-021-06790-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06790-5