Abstract

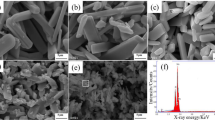

The powder synthesis conditions were controlled to prepare several phases of molybdenum (Mo) oxide having various morphologies in the ultrasonic spray pyrolysis process. Mo oxide was synthesized from the precursor ammonium heptamolybdate tetrahydrate (AHM). The spherical orthorhombic α-phase MoO3 and monoclinic β-phase MoO3 particles were prepared by controlling the synthesis temperature. Also, the belt-shaped α-phase MoO3 membrane with a length of several micro- to millimeters was formed by increasing the reaction temperature. The collection of the powder was adjusted with the position from the front- to back-collecting zone to reduce the occurrence of unnecessary condensation and the powder loss during the process. In addition, different amounts of polymers such as polyvinylpyrrolidone (PVP) and polyacrylic acid (PAA) were added in the precursor solution to control the structural properties of molybdenum oxide. The sprayable conditions of the precursor solution containing each polymer with different concentrations were investigated to set up the additional amounts of the polymer. The morphology was controlled to the spherical particles having a porous or hollow structure depending on the type and amount of polymer in the precursor solution. At the same time, the multiphase powders were prepared in which MoO3 was reduced to Mo4O11 and MoO2 by the effect of carbon monoxide (CO) produced by the thermal decomposition of the polymer.

Graphical abstract

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

Lipetzky P (2002) Refractory metals: a primer. JOM 54(3):47–49

Nemat-Nasser S, Guo W, Liu M (1999) Experimentally-based micromechanical modeling of dynamic response of molybdenum. Scr mater 40(7):859–872. https://doi.org/10.1016/s1359-6462(99)00041-x

Jiang XL, Boulos M (2006) Induction plasma spheroidization of tungsten and molybdenum powders. Trans Nonferrous Met Soc China 16(1):13–17. https://doi.org/10.1016/s1003-6326(06)60003-4

Feng HK, Cai ZY, Li YG, Qi YF (2014) Domestic and overseas research status on molybdenum resources and its use. Adv Mater Res 834:401–406. https://doi.org/10.4028/www.scientific.net/AMR.834-836.401

Ellefson CA, Marin-Flores O, Ha S, Norton M (2011) Synthesis and applications of molybdenum (IV) oxide. J Mater Sci 47(5):2057–2071

Wang L, Zhang GH, Chou KC (2016) Mechanism and kinetic study of hydrogen reduction of ultra-fine spherical MoO3 to MoO2. Int J Refract Met Hard Mater 54:342–350. https://doi.org/10.1016/j.ijrmhm.2015.09.003

Dang J, Zhang GH, Chou KC (2014) Phase transitions and morphology evolutions during hydrogen reduction of MoO3 to MoO2. High Temp Mater Processes 33(4):305–312. https://doi.org/10.1515/htmp-2013-0061

Kaiser F, Schmidt M, Grin Y, Veremchuk I (2020) Molybdenum oxides MoOx: Spark-plasma synthesis and thermoelectric properties at elevated temperature. Chem Mater 32(5):2025–2035. https://doi.org/10.1021/acs.chemmater.9b05075

Leisegang T, Levin AA, Walter J, Meyer DC (2005) In situ X-ray analysis of MoO3 reduction. Cryst Res Technol 40(1–2):95–105. https://doi.org/10.1002/crat.200410312

Yang X, Tang H, Zhang R, Song H, Cao K (2011) synthesis of high-quality crystalline α-MoO3 nanobelts. Cryst Res Technol 46(4):409–412. https://doi.org/10.1002/crat.201100061

Nagyné-Kovács T, Studnicka L, Lukács IE, László K, Pasierb P, Szilágyi IM, Pokol G (2020) Hydrothermal synthesis and gas sensing of monoclinic MoO3 nanosheets. Nanomaterials 10(5):891. https://doi.org/10.3390/nano10050891

Farzi-kahkesh S, Rahmani MB, Fattah A (2020) Growth of novel α-MoO3 hierarchical nanostructured thin films for ethanol sensing. Mater Sci Semicond Process 120:105263. https://doi.org/10.1016/j.mssp.2020.105263

Yao DD, Ou JZ, Latham K, Zhuiykov S, O’Mullane AP, Kalantar-zadeh K (2012) Electrodeposited α-and β-phase MoO3 films and investigation of their gasochromic properties. Cryst Growth Des 12(4):1865–1870. https://doi.org/10.1021/cg201500b

Mendoza-Sánchez B, Brousse T, Ramirez-Castro C, Nicolosi V, Grant PS (2013) An investigation of nanostructured thin film α-MoO3 based supercapacitor electrodes in an aqueous electrolyte. Electrochim Acta 91:253–260. https://doi.org/10.1016/j.electacta.2012.11.127

Liu X, Wu Y, Wang H, Wang Y, Huang C, Liu L, Wang Z (2020) Two-dimensional β-MoO3@C nanosheets as high-performance negative materials for supercapacitors with excellent cycling stability. RSC Adv 10(30):17497–17505. https://doi.org/10.1039/d0ra01258k

Sasidharan M, Gunawardhana N, Noma H, Yoshio M, Nakashima K (2012) α-MoO3 hollow nanospheres as an anode material for li-ion batteries. Bull Chem Soc Jpn 85(5):642–646. https://doi.org/10.1246/bcsj.20110375

Mariotti D, Lindström H, Bose AC, Ostrikov KK (2008) Monoclinic β-MoO3 nanosheets produced by atmospheric microplasma: application to lithium-ion batteries. Nanotechnology 19(49):495302. https://doi.org/10.1088/0957-4484/19/49/495302

Paraguay-Delgado F, Albiter MA, Huirache-Acuña R, Verde Y, Alonso-Nuñez G (2007) Optimization of the synthesis of α-MoO3 nanoribbons and hydrodesulfurization (HDS) Catalyst Test. J Nanosci Nanotechnol 7(10):3677–3683. https://doi.org/10.1166/jnn.2007.806

Mizushima T, Fukushima K, Ohkita H, Kakuta N (2007) Synthesis of β-MoO3 through evaporation of HNO3-added molybdic acid solution and its catalytic performance in partial oxidation of methanol. Appl Catal A 326(1):106–112. https://doi.org/10.1016/j.apcata.2007.04.006

Rao M, Ravindranadh K, Kasturi A, Shekhawat M (2013) Structural stoichiometry and phase transitions of MoO3 thin films for solid state microbatteries. Res J Recent Sci 2(4):67–73

Chiang TH, Yeh HC (2013) The synthesis of α-MoO3 by ethylene glycol. Materials 6(10):4609–4625. https://doi.org/10.3390/ma6104609

Pham TTP, Nguyen PHD, Vo TT, Nguyen HHP, Luu CL (2015) Facile method for synthesis of nanosized β–MoO3 and their catalytic behavior for selective oxidation of methanol to formaldehyde. Adv Nat Sci: Nanosci Nanotechnol 6(4):045010. https://doi.org/10.1088/2043-6262/6/4/045010

Li Y, Song Z, Li Y, Li S, Wang H, Song B, Gao B, Du X (2019) Synthesis of Mo4O11@MoO3 nanobelts and their improved sensing performance to NO2 gas. Mater Res Express 6(5):055041. https://doi.org/10.1088/2053-1591/ab0689

Hu B, Mai L, Chen W, Yang F (2009) From MoO3 nanobelts to MoO2 nanorods: structure transformation and electrical transport. ACS Nano 3(2):478–482. https://doi.org/10.1021/nn800844h

Chen D, Liu M, Yin L et al (2011) Single-crystalline MoO3 nanoplates: topochemical synthesis and enhanced ethanol-sensing performance. J Mater Chem 21(25):9332–9342. https://doi.org/10.1039/c1jm11447f

Zhou Y, Xie H, Wang C et al (2017) Probing lithium storage mechanism of MoO2 nanoflowers with rich oxygen-vacancy grown on graphene sheets. J Phys Chem C 121(29):15589–15596. https://doi.org/10.1021/acs.jpcc.7b04533

Yuan Z, Si L, Wei D, Hu L, Zhu Y, Li X, Qian Y (2014) Vacuum topotactic conversion route to mesoporous orthorhombic MoO3 nanowire bundles with enhanced electrochemical performance. J Phys Chem C 118(10):5091–5101. https://doi.org/10.1021/jp410550v

Gu S, Qin M, Zhang H, Ma J, Wu H, Qu X (2017) Facile solution combustion synthesis of MoO2 nanoparticles as efficient photocatalysts. CrystEngComm 19(43):6516–6526. https://doi.org/10.1039/C7CE01611E

Taurino AM, Forleo A, Francioso L, Siciliano P, Stalder M, Nesper R (2006) Synthesis, electrical characterization, and gas sensing properties of molybdenum oxide nanorods. Appl Phys Lett 88(15):152111. https://doi.org/10.1063/1.2192571

Zhao D, Zhang X, Huan H et al (2019) Facile synthesis of MoO3 nanospheres and their application in water treatment. Mater Lett 256:126648. https://doi.org/10.1016/j.matlet.2019.126648

Choi H, Yoon SP, Han J, Kim J, Othman MR (2017) Continuous synthesis of molybdenum oxide microspheres by ultrasonic spray pyrolysis. J Ind Eng Chem 47:254–259. https://doi.org/10.1016/j.jiec.2016.11.041

Zeggar ML, Chabane L, Aida MS, Attaf N, Zebbar N (2015) Solution flow rate influence on properties of copper oxide thin films deposited by ultrasonic spray pyrolysis. Mater Sci Semicond Process 30:645–650. https://doi.org/10.1016/j.mssp.2014.09.026

Im K, Kim D, Jang JH, Kim J, Yoo SJ (2020) Hollow-sphere Co-NC synthesis by incorporation of ultrasonic spray pyrolysis and pseudomorphic replication and its enhanced activity toward oxygen reduction reaction. Appl Catal B 260:118192. https://doi.org/10.1016/j.apcatb.2019.118192

Sen S, Dzwiniel T, Pupek K, Krumdick G, Tkac P, Vandegrift GF (2016) Process R&D for Particle Size Control of Molybdenum Oxide. Argonne National Lab.(ANL), Argonne, IL (United States).

Comini E, Yubao L, Brando Y, Sberveglieri G (2005) Gas sensing properties of MoO3 nanorods to CO and CH3OH. Chem Phys Lett 407(4–6):368–371. https://doi.org/10.1016/j.cplett.2005.03.116

Jittiarporn P, Sikong L, Kooptarnond K, Taweepreda W (2015) Influence of calcination temperature on the structural and photochromic properties of nanocrystalline MoO3. Dig J Nanomater Biostruct 10(4):1237–1248

Hou X, Huang J, Liu M, Li X, Hu Z, Feng Z, Zhang M, Luo J (2018) Single-crystal MoO3 micrometer and millimeter belts prepared from discarded molybdenum disilicide heating elements. Sci rep 8(1):1–8. https://doi.org/10.1038/s41598-018-34849-y

Liu H, Lin M, Guo S (2021) Morphological and structural evolutions of α-MoO3 single crystal belts towards MoS2/MoO2 heterostructures upon post-growth thermal vapor sulfurization. Appl Surf Sci 536:147956. https://doi.org/10.1016/j.apsusc.2020.147956

Ngo CM, Nguyen HD, Saito N, Do TMD, Nakayama T, Niihara K, Suematsu H (2021) Synthesis of β-MoO3 whiskers by the thermal evaporation method with flowing oxygen gas. J Am Ceram Soc. https://doi.org/10.1111/jace.18192

McCarron EM (1986) β-MoO3: a metastable analogue of WO3. J Chem Soc Chem Commun 4:336–338. https://doi.org/10.1039/C39860000336

German RM (1984) Powder metallurgy science 2nd ed. Metal Powder Industries Federation, U.S.A.

Ejim CE, Rahman MA, Amirfazli A, Fleck BA (2010) Effects of liquid viscosity and surface tension on atomization in two-phase, gas/liquid fluid coker nozzles. Fuel 89(8):1872–1882. https://doi.org/10.1016/j.fuel.2010.03.005

Shafeeq KM, Rizwana E, Kishor CR, Aneesh PM (2019) Growth and characterization of α-MoO3 thin films grown by spray pyrolysis technique. AIP Conf Proc 2082(1):050010. https://doi.org/10.1063/1.5093870

Samsuri A, Saharuddin TST, Salleh F, Othaman R, Hisham MWM, Ambar Yarmo M (2016) Temperature programmed reduction and x-ray diffractometry studies of MoO3 reduction by different concentration of carbon monoxide. Malays J Anal Sci 20(2):382–387

Wang P, Zhang Y, Yin Y, Fan L, Zhang N, Sun K (2018) Anchoring hollow MoO2 spheres on graphene for superior lithium storage. Chem Eng J 334:257–263. https://doi.org/10.1016/j.cej.2017.10.009

Majerič P, Rudolf R (2020) Advances in ultrasonic spray pyrolysis processing of noble metal nanoparticles. Mater 13(16):3485. https://doi.org/10.3390/ma13163485

Li B, Shao X, Hao Y, Zhao Y (2015) Ultrasonic-spray-assisted synthesis of metal oxide hollow/mesoporous microspheres for catalytic CO oxidation. RSC adv 5(104):85640–85645. https://doi.org/10.1039/x0xx00000x

Acknowledgements

This work was supported by the Technology Innovation Program (or Industrial Strategic technology development program, 20011286) funded By the Ministry of Trade, Industry and Energy (MI, Korea)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that there is no conflict of interest to disclose.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, S., Roh, J., Kim, M. et al. Effects of synthesis temperature and polymer addition on the phase and morphology of molybdenum oxide by ultrasonic spray pyrolysis. J Mater Sci 57, 18000–18013 (2022). https://doi.org/10.1007/s10853-022-07126-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07126-7