Abstract

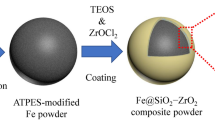

Here, we demonstrate a novel Fe@SiO2-powder-based soft magnetic composite that can withstand high-temperature heat treatment and that exhibits unprecedented mechanical strength. Fe@SiO2 powders are prepared by forming a uniform and continuous SiO2 insulation layer on the surface of Fe powder through sol–gel method based on a hydrolysis and condensation reaction mechanism. The sol–gel kinetics responded with a different tetraethyl orthosilicate (TEOS) concentration in the solution from 0.01 to 0.25 ml/g; SiO2 reactant is produced at different rates and accumulates at different thicknesses on the surfaces of Fe powders. The SMC core with dense and uniform SiO2 insulating layer contributes to better magnetic performance, including much higher electrical resistance, lower eddy current loss, and better frequency stability compared to those characteristics of the conductive Fe-based powder core. Furthermore, Fe@SiO2 SMC maintains its internal insulation matrix and low core loss even after high-temperature heat treatment, which densifies the SiO2 insulation layer and greatly enhances the mechanical strength of the SMCs. As a result, the Fe@SiO2 SMC core with an optimally controlled insulation thickness not only demonstrated a remarkably low core loss of 98 W/kg at 1 kHz and 500 mT but also a high mechanical flexural strength of 82 MPa, attributable to the uniform and dense internal SiO2 insulating matrix with high-temperature annealing resistance.

Similar content being viewed by others

References

Talaat A, Suraj MV, Byerly K, Wang A, Wang Y, Lee JK, Ohodnicki PR Jr (2021) Review on soft magnetic metal and inorganic oxide nanocomposites for power applications. J Alloys Compd 870:159500

Périgo EA, Weidenfeller B, Kollár P, Füzer J (2018) Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 5:031301

Shokrollahi HEJK, Janghorban K (2007) Soft magnetic composite materials (SMCs). J Mater Process Technol 189(1–3):1–12

Persson M, Jansson P, Jack AG, Mecrow BC (1995) Soft magnetic composite materials-use for electrical machines. Conf Publ 41:242–246

Guo Y, Zhu JG, Watterson PA, Wu W (2003) Comparative study of 3-D flux electrical machines with soft magnetic composite cores. IEEE Trans Ind Appl 39(6):1696–1703

Wang J, Wu Z, Li G (2016) Intergranular insulated Fe/SiO2 soft magnetic composite for decreased core loss. Adv Powder Technol 27(4):1189–1194

Wu S, Sun A, Lu Z, Cheng C, Gao X (2015) Magnetic properties of iron-based soft magnetic composites with SiO2 coating obtained by reverse microemulsion method. J Magn Magn Mater 381:451–456

Zhao YW, Zhang XK, Xiao JQ (2005) Submicrometer laminated Fe/SiO2 soft magnetic composites—an effective route to materials for high-frequency applications. Adv Mat 17(7):915–918

Yaghtin M, Taghvaei AH, Hashemi B, Janghorban K (2013) Effect of heat treatment on magnetic properties of iron-based soft magnetic composites with Al2O3 insulation coating produced by sol–gel method. J Alloys Compd 581:293–297

Peng Y, Yi Y, Li L, Yi J, Nie J, Bao C (2016) Iron-based soft magnetic composites with Al2O3 insulation coating produced using sol–gel method. Mater Des 109:390–395

Lei J, Zheng J, Zheng H, Qiao L, Ying Y, Cai W, Li W, Yu J, Lin M, Che S (2019) Effects of heat treatment and lubricant on magnetic properties of iron-based soft magnetic composites with Al2O3 insulating layer by one-pot synthesis method. J Magn Magn Mater 472:7–13

Zhang D, Qin M, Huang M, Wu T, Jia B, Wu H, Ma J, Chen G, Qu X (2019) Magnetic properties of evenly mixed Fe-Y2O3 nanocomposites synthesized by a facile wet-chemical based route. J Magn Magn Mater 491:165576

Geng K, Xie Y, Xu L, Yan B (2017) Structure and magnetic properties of ZrO2-coated Fe powders and Fe/ZrO2 soft magnetic composites. Adv Powder Technol 28(9):2015–2022

Li W, Wang Z, Ying Y, Yu J, Zheng J, Qiao L, Che S (2019) In-situ formation of Fe3O4 and ZrO2 coated Fe-based soft magnetic composites by hydrothermal method. Ceram Int 45(3):3864–3870

Back JA, Schaeffer L, Gaio JC (2020) Study of the electromagnetic properties of a soft magnetic composite (SMC) and its efficiency when applied to a low frequency magnetic field. Int J Eng 9(6):1–9

Lee S, Choi M, Kim J (2017) Magnetic properties of pure iron soft magnetic composites coated by manganese phosphates. IEEE Trans Magn 53(11):1–4

Zhou B, Dong Y, Liu L, Chang L, Bi F, Wang X (2019) Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J Magn Magn Mater 474:1–8

Xiao HM, Liu XM, Fu SY (2006) Synthesis, magnetic and microwave absorbing properties of core-shell structured MnFe2O4/TiO2 nanocomposites. Compos Sci Technol 66(13):2003–2008

Pyo HJ, Jeong JW, Yu J, Nam DW, Yang SH, Kim WH (2020) Eddy current loss reduction in 3D-printed axial flux motor using 3D-printed SMC core. 2020 IEEE Energy Convers Congr Expo 1121–1125

Yang Y, Wang Y, Wu S, Liu C, Chen L (2021) Core loss analysis of soft magnetic composites considering the inter-particle eddy current loss. AIP Adv 11(1):015140

Yu X, Li Y, Yang Q, Yue S, Zhang C (2018) Loss characteristics and model verification of soft magnetic composites under non-sinusoidal excitation. IEEE Trans Magn 55(2):1–4

Kollár P, Birčáková Z, Füzer J, Bureš R, Fáberová M (2013) Power loss separation in Fe-based composite materials. J Magn Magn Mater 327:146–150

Paplicki P, Wardach M, Bonisławski M, Pałka R (2015) Simulation and experimental results of hybrid electric machine with a novel flux control strategy. Arch Electr Eng 64(1):37–51

Dou Y, Guo Y, Zhu J (2007) Investigation of motor topologies for SMC application. Int Conf Electr Mach Syst 695–698

Taghvaei AH, Shokrollahi H, Janghorban K (2009) Properties of iron-based soft magnetic composite with iron phosphate–silane insulation coating. J Alloys Compd 481(1–2):681–686

Yang B, Wu Z, Zou Z, Yu R (2010) High-performance Fe/SiO2 soft magnetic composites for low-loss and high-power applications. J Phys D Appl Phys 43(36):365003

Wang J, Fan XA, Wu Z, Li G (2017) Regulation and control of insulated layers for intergranular insulated Fe/SiO2 soft magnetic composites. J Mater Sci 52(12):7091–7099. https://doi.org/10.1007/s10853-017-0941-9

Tang NJ, Jiang HY, Zhong W, Wu XL, Zou WQ, Du YW (2006) Synthesis and magnetic properties of Fe/SiO2 nanocomposites prepared by a sol–gel method combined with hydrogen reduction. J Alloys Compd 419(1–2):145–148

Jang MS, Chang MS, Kwon YT, Yang S, Gwak J, Kwon SJ, Lee J, Song K, Park CR, Lee SB, Park B, Jeong JW (2021) High-throughput thermal plasma synthesis of Fe xCo1-x nano-chained particles with unusually-high permeability, and their electromagnetic wave absorption properties at high frequency (1–26 GHz). Nanoscale 13:12004–12016

Jian-Ping W, He-Lie L (1994) Preparation and properties of pure nanocomposite Fe-SiO2 using the sol-gel method. J Magn Magn Mater 131(1–2):54–60

Matsoukas T, Gulari E (1988) Dynamics of growth of silica particles from ammonia-catalyzed hydrolysis of tetra-ethyl-orthosilicate. J Colloid Interface Sci 124:252–261

Matsoukas T, Gulari E (1988) Monomer-addition growth with a slow initiation step: A growth model for silica particles from alkoxides. J Colloid Interface Sci 132(1):13–21

Kim Y, Qian Y, Kim M, Ju J, Baeck SH, Shim SE (2017) A one-step process employing various amphiphiles for an electrically insulating silica coating on graphite. RSC Adv 7(39):24242–24254

Zhou B, Dong Y, Chi Q, Zhang Y, Chang L, Gong M, Huang J, Pan Y, Wang X (2020) Fe-based amorphous soft magnetic composites with SiO2 insulation coatings: A study on coatings thickness, microstructure and magnetic properties. Ceram Int 46(9):13449–13459

Jang MS, Chang MS, Kwon YT, Yang S, Gwak J, Kwon SJ, Song K, Park CR, Lee SB, Park BJ, Jeong JW (2021) High-throughput thermal plasma synthesis of FexCo1-x nano-chained particles with unusually high permeability and their electromagnetic wave absorption properties at high frequency (1–26 GHz). Nanoscale 13(27):12004–12016

Chang YW, Kim WS, Kim WS (1996) Effect of reaction conditions on size and morphology of SiO2 powder in a sol-gel process. Korean J Chem Eng 13:496–502

De G, Karmakar B, Ganguli D (2000) Hydrolysis–condensation reactions of TEOS in the presence of acetic acid leading to the generation of glass-like silica microspheres in solution at room temperature. J Mater Chem 10(10):2289–2293

Van Bommel MJ, Bernards TNM, Boonstra AH (1991) The influence of the addition of alkyl-substituted ethoxysilane on the hydrolysis—condensation process of TEOS. J Non Cryst Solids 128(3):231–242

Rubio F, Rubio J, Oteo JL (1998) A FT-IR study of the hydrolysis of tetraethylorthosilicate (TEOS). Spectrosc Lett 31(1):199–219

Park S, Seo H, Seol D, Yoon YH, Kim MY, Kim Y (2016) Probing of multiple magnetic responses in magnetic inductors using atomic force microscopy. Sci Rep 6(1):1–8

Hemmati I, Hosseini HM, Kianvash A (2006) The correlations between processing parameters and magnetic properties of an iron–resin soft magnetic composite. J Magn Magn Mater 305(1):147–151

Zhu JG, Zhong JJ, Ramsden VS, Guo YG (1999) Power losses of soft magnetic composite materials under two-dimensional excitation. J Appl Phys 85(8):4403–4405

Guo Y, Zhu JG, Zhong JJ, Wu W (2003) Core losses in claw pole permanent magnet machines with soft magnetic composite stators. IEEE Trans Magn 39(5):3199–3201

Al-Homoud MS (2005) Performance characteristics and practical applications of common building thermal insulation materials. Build Environ 40(3):353–366

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (NRF-2020M3H4A310563413, NRF-2020M3H4A3105641 and NRF-2021M3D1A204772411).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jang, MS., Park, JM., Kang, J. et al. Soft magnetic composites with improved heat resistance and mechanical strength realized using Fe@SiO2 powders with a variable thickness insulation layer. J Mater Sci 57, 18118–18130 (2022). https://doi.org/10.1007/s10853-022-07517-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07517-w