Abstract

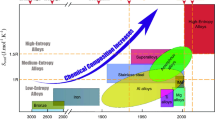

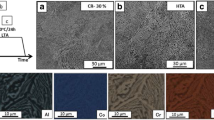

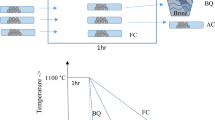

Multi-phase structure alloys have been widely used in superplasticity deformation due to their ability to inhibit grain growth. However, the current study on multi-phase structure alloys has mainly indicated static grain growth than dynamic grain growth. Dynamic grain growth plays an important role in superplastic deformation because it leads to strain hardening, limiting superplastic elongation. In this research, the Al0.5CoCrFeMnNi high-entropy alloy (HEA) was annealed at 1473 K for 2 h to form a single-phase FCC microstructure, then subjected to high-pressure torsion (HPT) for grain refinement. This HEA achieved high-strain rate superplasticity with an impressive elongation of 1100% under a temperature of 1073 K at a strain rate of 10–1 s−1. Comparing the results of the present study with a previous work published on the same HEA reveals the impact of initial annealing on the superplastic response. It is suggested that the initial B2, formed during the annealing stage before the HPT process, effectually limits the dynamic grain growth, resulting in remarkably enhanced superplasticity. This investigation introduces the new microstructural evolution to uplift superplasticity in multi-phase structures with dynamic grain growth elimination.

Graphical abstract

Similar content being viewed by others

Data availability

The data supporting this study's findings are available from the corresponding author upon reasonable request.

References

Langdon TG (2009) Seventy-five years of superplasticity: historic developments and new opportunities. J Mater Sci 44:5998–6010. https://doi.org/10.1007/s10853-009-3780-5

McFadden SX, Mishra RS, Valiev RZ, Zhilyaev AP, Mukherjee AK (1999) Low-temperature superplasticity in nanostructured nickel and metal alloys. Nature 398:684–686. https://doi.org/10.1038/19486

Langdon TG (2006) Grain boundary sliding revisited: Developments in sliding over four decades. J Mater Sci 41:597–609. https://doi.org/10.1007/s10853-006-6476-0

Liu FC, Ma ZY (2010) Contribution of grain boundary sliding in low-temperature superplasticity of ultrafine-grained aluminum alloys. Scr Mater 62:125–128. https://doi.org/10.1016/j.scriptamat.2009.10.010

Alabort E, Barba D, Shagiev MR, Murzinova MA, Galeyev RM, Valiakhmetov OR, Aletdinov AF, Reed RC (2019) Alloys-by-design: Application to titanium alloys for optimal superplasticity. Acta Mater 178:275–287. https://doi.org/10.1016/j.actamat.2019.07.026

Kawasaki M, Langdon TG (2007) Principles of superplasticity in ultrafine-grained materials. J Mater Sci 42:1782–1796. https://doi.org/10.1007/s10853-006-0954-2

Langdon TG (1994) An evaluation of the strain contributed by grain boundary sliding in superplasticity. Mater Sci Eng A 174:225–230. https://doi.org/10.1016/0921-5093(94)91092-8

Venkataraman A, Linne M, Daly S, Sangid MD (2019) Criteria for the prevalence of grain boundary sliding as a deformation mechanism. Materialia 8:100499. https://doi.org/10.1016/j.mtla.2019.100499

Musin F, Kaibyshev R, Motohashi Y, Itoh G (2004) High strain rate superplasticity in a commercial Al–Mg–Sc alloy. Scr Mater 50:511–516. https://doi.org/10.1016/j.scriptamat.2003.10.021

Barnes AJ (2001) Industrial applications of superplastic forming: trends and prospects. Mater Sci Forum 357–359:3–16. https://doi.org/10.4028/www.scientific.net/MSF.357-359.3

Dursun T, Soutis C (2014) Recent developments in advanced aircraft aluminium alloys. Mater Des 56:862–871. https://doi.org/10.1016/j.matdes.2013.12.002

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45:103–189. https://doi.org/10.1016/S0079-6425(99)00007-9

Shaysultanov DG, Stepanov ND, Kuznetsov AV, Salishchev GA, Senkov ON (2013) Phase composition and superplastic behavior of a wrought AlCoCrCuFeNi high-entropy alloy. JOM 65:1815–1828. https://doi.org/10.1007/s11837-013-0754-5

Zhang D, Wang S, Qiu C, Zhang W (2012) Superplastic tensile behavior of a fine-grained AZ91 magnesium alloy prepared by friction stir processing. Mater Sci Eng A 556:100–106. https://doi.org/10.1016/j.msea.2012.06.063

Nasiri Z, Ghaemifar S, Naghizadeh M, Mirzadeh H (2021) Thermal mechanisms of grain refinement in steels: a review. Met Mater Int 27:2078–2094. https://doi.org/10.1007/s12540-020-00700-1

Lin HK, Huang JC, Langdon TG (2005) Relationship between texture and low temperature superplasticity in an extruded AZ31 Mg alloy processed by ECAP. Mater Sci Eng A 402:250–257. https://doi.org/10.1016/j.msea.2005.04.018

Asghari-Rad P, Sathiyamoorthi P, Nguyen NTC, Bae JW, Shahmir H, Kim HS (2020) Fine-tuning of mechanical properties in V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy through high-pressure torsion and annealing. Mater Sci Eng A 771:138604. https://doi.org/10.1016/j.msea.2019.138604

Asghari-Rad P, Sathiyamoorthi P, Nguyen NTC, Zargaran A, Kim TS, Kim HS (2021) A powder-metallurgy-based fabrication route towards achieving high tensile strength with ultra-high ductility in high-entropy alloy. Scr Mater 190:69–74. https://doi.org/10.1016/j.scriptamat.2020.08.038

Hadi S, Rahimzadeh Lotfabad F, Paydar MH, Ebrahimi F (2021) New mathematical stress analysis in the compressive stage of the high-pressure torsion process. Met Mater Int 27:2947–2956. https://doi.org/10.1007/s12540-020-00881-9

Coury FG, Zepona G, Bolfarini C (2021) Multi-principal element alloys from the CrCoNi family: outlook and perspectives. J Mater Res Technol 15:3461–3480. https://doi.org/10.1016/j.jmrt.2021.09.095

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122:448–511. https://doi.org/10.1016/j.actamat.2016.08.081

Otto F, Dlouhý A, Pradeep KG, Kuběnová M, Raabe D, Eggeler G, George EP (2016) Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater 112:40–52. https://doi.org/10.1016/j.actamat.2016.04.005

Miracle D (2019) High entropy alloys as a bold step forward in alloy development. Nat Commun 10:1805. https://doi.org/10.1038/s41467-019-09700-1

Tsai MH, Yeh JW (2014) High-entropy alloys: a critical review. Mater Res Lett 2:107–123. https://doi.org/10.1080/21663831.2014.912690

Yi J, Yang L, Wang L, Xu M (2022) Lightweight, refractory high-entropy alloy, CrNbTa0.25TiZr, with high yield strength. Met Mater Int 28:448–455. https://doi.org/10.1007/s12540-021-01059-7

Wang H, Hu Z, Cao J, Zhang S, Cheng T, Wang Q (2022) Hot deformation and workability of a CrCoNi medium entropy alloy. Met Mater Int 28:514–522. https://doi.org/10.1007/s12540-021-01057-9

Reddy S, Bapari S, Bhattacharjee PP, Chokshi A (2017) Superplastic-like flow in a fine-grained equiatomic CoCrFeMnNi high-entropy alloy. Mater Res Lett 5:408–414. https://doi.org/10.1080/21663831.2017.1305460

Shahmir H, Nili-Ahmadabadi M, Shafiee A, Langdon TG (2018) Effect of a minor titanium addition on the superplastic properties of a CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Mater Sci Eng A 718:468–476. https://doi.org/10.1016/j.msea.2018.02.002

Nguyen NTC, Moon J, Sathiyamoorthi P, Asghari-Rad P, Kim GH, Lee CS, Kim HS (2019) Superplasticity of V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy processed using high-pressure torsion. Mater Sci Eng A 764:138198. https://doi.org/10.1016/j.msea.2019.138198

Shahmir H, He J, Lu Z, Kawasaki M, Langdon TG (2017) Evidence for superplasticity in a CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Mater Sci Eng A 685:342–348. https://doi.org/10.1016/j.msea.2017.01.016

Nguyen TCN, Asghari-Rad P, Sathiyamoorthi P, Zargaran A, Lee CS, Kim HS (2020) Ultrahigh high-strain-rate superplasticity in a nanostructured high-entropy alloy. Nat Commun 11:1–7. https://doi.org/10.1038/s41467-020-16601-1

Asghari-Rad P, Nguyen TCN, Zargaran A, Sathiyamoorthi P, Kim HS (2022) Deformation-induced grain boundary segregation mediated high-strain rate superplasticity in medium entropy alloy. Scr Mater 207:114239. https://doi.org/10.1016/j.scriptamat.2021.114239

Nguyen NTC, Asghari-Rad P, Bae JW, Sathiyamoorthi P, Kim HS (2021) Superplastic behavior in high-pressure torsion-processed Mo7.5Fe55Co18Cr12.5Ni7 medium-entropy alloy. Metall Mater Trans A 52:1–7. https://doi.org/10.1007/s11661-020-06033-3

Sohn SS, Kim DG, Jo YH, da Silva AK, Lu W, Breen AJ, Gault B, Ponge D (2020) High-rate superplasticity in an equiatomic medium-entropy VCoNi alloy enabled through dynamic recrystallization of a duplex microstructure of ordered phases. Acta Mater 194:106–117. https://doi.org/10.1016/j.actamat.2020.03.048

Nguyen NTC, Asghari-rad P, Zargaran A, Kim ES, Sathiyamoorthi P, Kim HS (2022) Relation of phase fraction to superplastic behavior of multi-principal element alloy with a multi-phase structure. Scr Mater (Accepted). https://doi.org/10.1016/j.scriptamat.2022.114949

Jeong HT, Kim WJ (2021) Microstructure tailoring of Al0.5CoCrFeMnNi to achieve high strength and high uniform strain using severe plastic deformation and an annealing treatment. J Mater Sci Technol 71:228–240. https://doi.org/10.1016/j.jmst.2020.07.017

Ye YF, Wang Q, Lu J, Liu CT, Yang Y (2016) High-entropy alloy: challenges and prospects. Mater Today 19:349–362. https://doi.org/10.1016/j.mattod.2015.11.026

Reddy TS, Wani IS, Bhattacharjee Y, Reddy SR, Saha R, Bhattacharjeea PP (2017) Severe plastic deformation driven nanostructure and phase evolution in a Al0.5CoCrFeMnNi dual phase high entropy alloy. Intermetallics 91:150–157. https://doi.org/10.1016/j.intermet.2017.09.002

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh TG, Lu ZP (2014) Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater 62:105–113. https://doi.org/10.1016/j.actamat.2013.09.037

Park JM, Moon J, Bae JW, Kim DH, Jo YH, Lee SH, Kim HS (2019) Role of BCC phase on tensile behavior of dual-phase Al0.5CoCrFeMnNi high-entropy alloy at cryogenic temperature. Mater Sci Eng A 746:443–447. https://doi.org/10.1016/j.msea.2019.01.041

Kim WJ, Jeong HT, Park HK, Park K, Na TW, Choi E (2019) The effect of Al to high-temperature deformation mechanisms and processing maps of Al0.5CoCrFeMnNi high entropy alloy. J Alloys Compd 802:152–165. https://doi.org/10.1016/j.jallcom.2019.06.099

Jeong HT, Kim WJ (2021) Calculation and construction of deformation mechanism maps and processing maps for CoCrFeMnNi and Al0.5CoCrFeMnNi high-entropy alloys. J Alloys Compd 869:159256. https://doi.org/10.1016/j.jallcom.2021.159256

Jeong HT, Park HK, Kim WJ (2022) Class I type creep behavior of coarse-grained Al0.5CoCrFeMnNi high entropy alloy. Mater Sci Eng A 845:143239. https://doi.org/10.1016/j.msea.2022.143239

Uporova SA, Ryltseva RE, Bykov VA, Estemirova SKh, Zamyatin DA (2020) Microstructure, phase formation and physical properties of AlCoCrFeNiMn high-entropy alloy. J Alloys Compd 820:153228. https://doi.org/10.1016/j.jallcom.2019.153228

Moon J, Bae JW, Jang MJ, BaeK SM, Yim D, Lee BJ, Kim HS (2018) Effects of homogenization temperature on cracking during cold-rolling of Al0.5CoCrFeMnNi high-entropy alloy. Mater Chem Phys 210:187–191. https://doi.org/10.1016/j.matchemphys.2017.06.043

Han J, Kang SH, Lee SJ, Kawasaki M, Lee HJ, Ponge D, Raabe D, Lee YK (2017) Superplasticity in a lean Fe–Mn–Al steel. Nat Commun 8:1–6. https://doi.org/10.1038/s41467-017-00814-y

Jéhanno P, Heilmaier M, Saage H, Heyse H, Böning M, Kestler H, Schneibel JH (2006) Superplasticity of a multiphase refractory Mo–Si–B alloy. Scr Mater 55:525–528. https://doi.org/10.1016/j.scriptamat.2006.05.033

Li Z, Yu J, Zheng X, Zhang J, Liu H, Bai R, Wang H, Wang D, Wang W (2011) Superplasticity of a multiphase fine-grained Mo–Si–B alloy. Powder Technol 214:54–56. https://doi.org/10.1016/j.powtec.2011.07.033

Mohamed FA, Li Y (2001) Creep and superplasticity in nanocrystalline materials: current understanding and future prospects. Mater Sci Eng A 298:1–15. https://doi.org/10.1016/S0928-4931(00)00190-9

McFadden S, Valiev R, Mukherjee A (2001) Superplasticity in nanocrystalline Ni3Al. Mater Sci Eng A 319:849–853. https://doi.org/10.1016/S0921-5093(01)01098-X

Schuh B, Mendez-Martin F, Völker B, George EP, Clemens H, Pippane R, Hohenwarter A (2015) Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater 96:258–268. https://doi.org/10.1016/j.actamat.2015.06.025

Wu X, Zhu Y (2017) Heterogeneous materials: a new class of materials with unprecedented mechanical properties. Mater Res Lett 5:527–532. https://doi.org/10.1080/21663831.2017.1343208

Huang L, Qi F, Yu L, Xin X, Liu F, Sun W, Hu Z (2015) Necking behavior and microstructural evolution during high strain rate superplastic deformation of IN718 superalloy. Mater Sci Eng A 634:71–76. https://doi.org/10.1016/j.msea.2015.03.031

Leng Z, Zhang J, Lin H, Fei P, Zhang L, Liu S, Zhang M, Wu R (2015) Superplastic behavior of extruded Mg–9RY–4Zn alloy containing long period stacking ordered phase. Mater Sci Eng A 576:202–206. https://doi.org/10.1016/j.msea.2013.04.005

Langdon TG (1982) Fracture processes in superplastic flow. Met Sci 16:175–183. https://doi.org/10.1179/030634582790427208

Masuda H, Kanazawa T, Tobe H, Sato E (2018) Dynamic anisotropic grain growth during superplasticity in Al–Mg–Mn alloy. Scr Mater 147:84–87. https://doi.org/10.1016/j.scriptamat.2018.02.021

Chuvil’deev VN, Gryaznov MY, Shotin SV, Kopylov VI, Nokhrin AV, Likhnitskii CV, Murashov AA, Bobrov AA, Tabachkova NY, Pirozhnikova OE (2021) Investigation of superplasticity and dynamic grain growth in ultrafine-grained Al–0.5% Mg–Sc alloys. J Alloys Compd 877:160099. https://doi.org/10.1016/j.jallcom.2021.160099

Watts BM, Stowell MJ, Cottingham DM (1971) The variation in flow stress and microstructure during superplastic deformation of the Al-Cu eutectic. J Mater Sci 6:228–237. https://doi.org/10.1007/BF00550018

Rabinovich MK, Trifonov VG (1996) Dynamic grain growth during superplastic deformation. Acta Mater 44:2073–2078. https://doi.org/10.1016/1359-6454(95)00263-4

Cao FR, Ding H, Li YL, Zhou G, Cui JZ (2010) Superplasticity, dynamic grain growth and deformation mechanism in ultra-light two-phase magnesium–lithium alloys. Mater Sci Eng A 527:2335–2341. https://doi.org/10.1016/j.msea.2009.12.029

Wilkinson DS, Caceres CH (1984) On the mechanism of strain-enhanced grain growth during superplastic deformation. Acta Metall 32:1335–1345. https://doi.org/10.1016/0001-6160(84)90079-8

Kim BN, Hiraga K, Morita K, Sakka Y (2001) A high-strain-rate superplastic ceramic. Nature 413:288–291. https://doi.org/10.1038/35095025

Kim BN, Hiraga K (2002) Superplastic ceramic deformable at high strain rates. Chem Eng Tech 25:1021–1023. https://doi.org/10.1002/1521-4125(20021008)25:10%3c1021::AID-CEAT1021%3e3.0.CO;2-8

Suryanarayana C, Al-Joubori AA, Wang Z (2022) Nanostructured materials and nanocomposites by mechanical alloying: an overview. Met Mater Int 28:41–53. https://doi.org/10.1007/s12540-021-00998-5

Mayo MJ (1997) High and low temperature superplasticity in nanocrystalline materials. Nanostruct Mater 9:717–726. https://doi.org/10.1016/S0965-9773(97)00158-X

Mishra RS, Valiev RZ, McFadden SX, Islamgaliev, RK, Mukherjee AK (2001) High-strain-rate superplasticity from nanocrystalline Al alloy 1420 at low temperatures. Philos Mag A 81:37–48. https://doi.org/10.1080/01418610108216616

Sato E, Kuribayashi K (1993) Superplasticity and deformation induced grain growth. ISIJ Int 33:825–832. https://doi.org/10.2355/isijinternational.33.825

Hyde KB, Bate PS (2005) Dynamic grain growth in Al–6Ni: modelling and experiments. Acta Mater 53:4313–4321. https://doi.org/10.1016/j.actamat.2005.05.029

Maier-Kiener V, Durst K (2017) Advanced nanoindentation testing for studying strain-rate sensitivity and activation volume. JOM 69:2246–2255. https://doi.org/10.1007/s11837-017-2536-y

Nazzal M, Khraisheh M, Abu-Farha FK (2007) The effect of strain rate sensitivity evolution on deformation stability during superplastic forming. Mater Process Technol 191:189–192. https://doi.org/10.1016/j.jmatprotec.2007.03.097

Kapoor R (2017) Severe plastic deformation of materials. Materials under extreme conditions: recent trends and future prospects. Elseviver pp 717–754. https://doi.org/10.1016/B978-0-12-801300-7.00020-6

Wei Q, Cheng S, Ramesh K, Ma E (2004) Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater Sci Eng A 381:71–79. https://doi.org/10.1016/j.msea.2004.03.064

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (NRF-2022R1A5A1030054). The authors acknowledge the technical support from Professor Chong Soo Lee, Mr. Geon Hyeong Kim, and Mr. Gyeong Hyeon Jang from Materials Reliability Laboratory, Graduate Institute of Ferrous & Energy Materials Technology (GIFT), Pohang University of Science and Technology, Pohang, South Korea.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nguyen, N.TC., Asghari-Rad, P., Park, H. et al. Differential superplasticity in a multi-phase multi-principal element alloy by initial annealing. J Mater Sci 57, 18154–18167 (2022). https://doi.org/10.1007/s10853-022-07616-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07616-8