Abstract

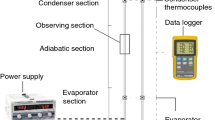

Visualization experiment is a must in realizing functional characteristics of an operational pulsating heat pipe (PHP). So far there is no general formulation which can foretell the complex and chaotic flow nature for every working fluid. Different response of working fluids and their distinct flow nature as well as their behavior can be visualized which thereby helps to understand the operational mechanism of the PHP. In this experiment, tests were conducted in a transparent PHP with 3 conventional working fluids, viz. de-ionized (DI) water, methanol, ethanol, and 300 ppm cetyltrimethyl ammonium chloride (CTAC) solution, each with fill ratio (FR) of 50%. With the help of high speed camera, flow characteristics at different operational stages for each working fluid are captured. Difference in the generation, growth, movement, and flow direction of bubbles are observed and the consequence of combined effects of various thermal properties of the fluid rather than a dominating single property. Start-up characteristics and dominating flow pattern for each fluid are reported in this paper. Moreover, peculiar flow characteristics with 300 ppm CTAC like bubble detachment, movement of cluster of micro-bubbles, and swirling are also presented.

Similar content being viewed by others

Change history

05 February 2022

A Correction to this paper has been published: https://doi.org/10.1007/s42757-022-0132-z

References

Akachi, H. 1990. Structure of a heat pipe. U.S. Patent No. 4,921,041. Washington, DC: U.S. Patent and Trademark Office.

Aly, W. I. A. 2014. Numerical study on turbulent heat transfer and pressure drop of nanofluid in coiled tube-in-tube heat exchangers. Energ Convers Manage, 79: 304–316.

Bastakoti, D., Zhang, H. N., Cai, W. H., Li, F. C. 2018a. An experimental investigation of thermal performance of pulsating heat pipe with alcohols and surfactant solutions. Int J Heat Mass Tran, 117: 1032–1040.

Bastakoti, D., Zhang, H. N., Li, D., Cai, W. H., Li, F. C. 2018b. An overview on the developing trend of pulsating heat pipe and its performance. Appl Therm Eng, 141: 305–332.

Bergles, A. E. 1985. Techniques to augment heat transfer. In: Handbook of Heat Transfer Application. Rohsenow, W. M., Hartnett, J. P., Ganie, E. Eds. New York: McGraw-Hill.

Fonseca, L. D., Miller, F., Pfotenhauer, J. 2015. Design and operation of a cryogenic nitrogen pulsating heat pipe. IOP Conf Ser: Mat Sci, 101: 012064.

Fumoto, K., Ishida, T., Kawanami, T., Inamura, T. 2016. Effect of working fluid in heat transport characteristics of pulsating heat pipe. Trans JSME, 82: 15–00529.

Han, X. H., Wang, X. H., Zheng, H. C., Xu, X. G., Chen, G. M. 2016. Review of the development of pulsating heat pipe for heat dissipation. Renew Sust Energ Rev, 59: 692–709.

Hetsroni, G., Zakin, J. L., Lin, Z., Mosyak, A., Pancallo, E. A., Rozenblit, R. 2001. The effect of surfactants on bubble growth, wall thermal patterns and heat transfer in pool boiling. Int J Heat Mass Tran, 44: 485–497.

Kearney, D. J., Suleman, O., Griffin, J., Mavrakis, G. 2016. Thermal performance of a PCB embedded pulsating heat pipe for power electronics applications. Appl Therm Eng, 98: 798–809.

Liang, Q. Q., Hao, T. T., Wang, K., Ma, X. H., Lan, Z., Wang, Y. X. 2018. Startup and transport characteristics of oscillating heat pipe using ionic liquids. Int Commun Heat Mass, 94: 1–13.

Liang, Q., Hao, T., Wang, K., Ma, X., Lan, Z., Wang, Y. 2016. Effect of ionic liquid on the startup and operation performance of the pulsating heat pipe. Journal of Engineering Thermophysics, 37: 2680–2683. (in Chinese)

Mangini, D., Ilinca, A. I., Mameli, M., Fioriti, D., Filippeschi, S., Araneo, L., Marengo, M. 2017. Single loop pulsating heat pipe with non-uniform heating patterns: Fluid infrared visualization and pressure measurements. In: Proceedings of the 9th World Conference on Experimental Heat Transfer, Fluid Mechanics and Thermodynamics.

Nazari, M. A., Ghasempour, R., Ahmadi, M. H., Heydarian, G., Shafii, M. B. 2018. Experimental investigation of graphene oxide nanofluid on heat transfer enhancement of pulsating heat pipe. Int Commun Heat Mass, 91: 90–94.

Qu, J., Wu, H. Y., Cheng, P. 2010. Thermal performance of an oscillating heat pipe with Al2O3—water nanofluids. Int Commun Heat Mass, 37: 111–115.

Qu, W., Ma, H. B. 2007. Theoretical analysis of startup of a pulsating heat pipe. Int J Heat Mass Tran, 50: 2309–2316.

Shafii, M. B., Faghri, A., Zhang, Y. W. 2002. Analysis of heat transfer in unlooped and looped pulsating heat pipes. Int J Numer Method H, 12: 585–609.

Spinato, G., Borhani, N., Thome, J. R. 2016. Operational regimes in a closed loop pulsating heat pipe. Int J Therm Sci, 102: 78–88.

Sun, Q., Qu, J., Li, X. J., Yuan, J. P. 2017. Experimental investigation of thermo-hydrodynamic behavior in a closed loop oscillating heat pipe. Exp Therm Fluid Sci, 82: 450–458.

Wang, J., Li, F. C., Li, X. B. 2016. On the mechanism of boiling heat transfer enhancement by surfactant addition. Int J Heat Mass Tran, 101: 800–806.

Wang, X. Y., Jia, L. 2016. Experimental study on heat transfer performance of pulsating heat pipe with refrigerants. J Therm Sci, 25: 449–453.

Wu, W. T., Yang, Y. M. 1992. Enhanced boiling heat transfer by surfactant additives. In: Proceedings of the Engineering Foundation Conference on Pool and External Flow Boiling, 361–366.

Acknowledgements

This paper is supported by the National Natural Science Foundation of China (Grant Nos. 51576051, 51606054, and 51776057). Zhang would like to thank the financial support of “Key Laboratory of Advanced Reactor Engineering and Safety, Ministry of Education (ARES-2018-01)”.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Basatakoti, D., Zhang, H., Li, X. et al. Visualization of bubble mechanism of pulsating heat pipe with conventional working fluids and surfactant solution. Exp. Comput. Multiph. Flow 2, 22–30 (2020). https://doi.org/10.1007/s42757-019-0033-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42757-019-0033-y